In this setup, you’ll optimize your production for Rotors by using 112.5

Iron Ore per minute to generate 10 Rotors.

This build uses no alternate recipies.

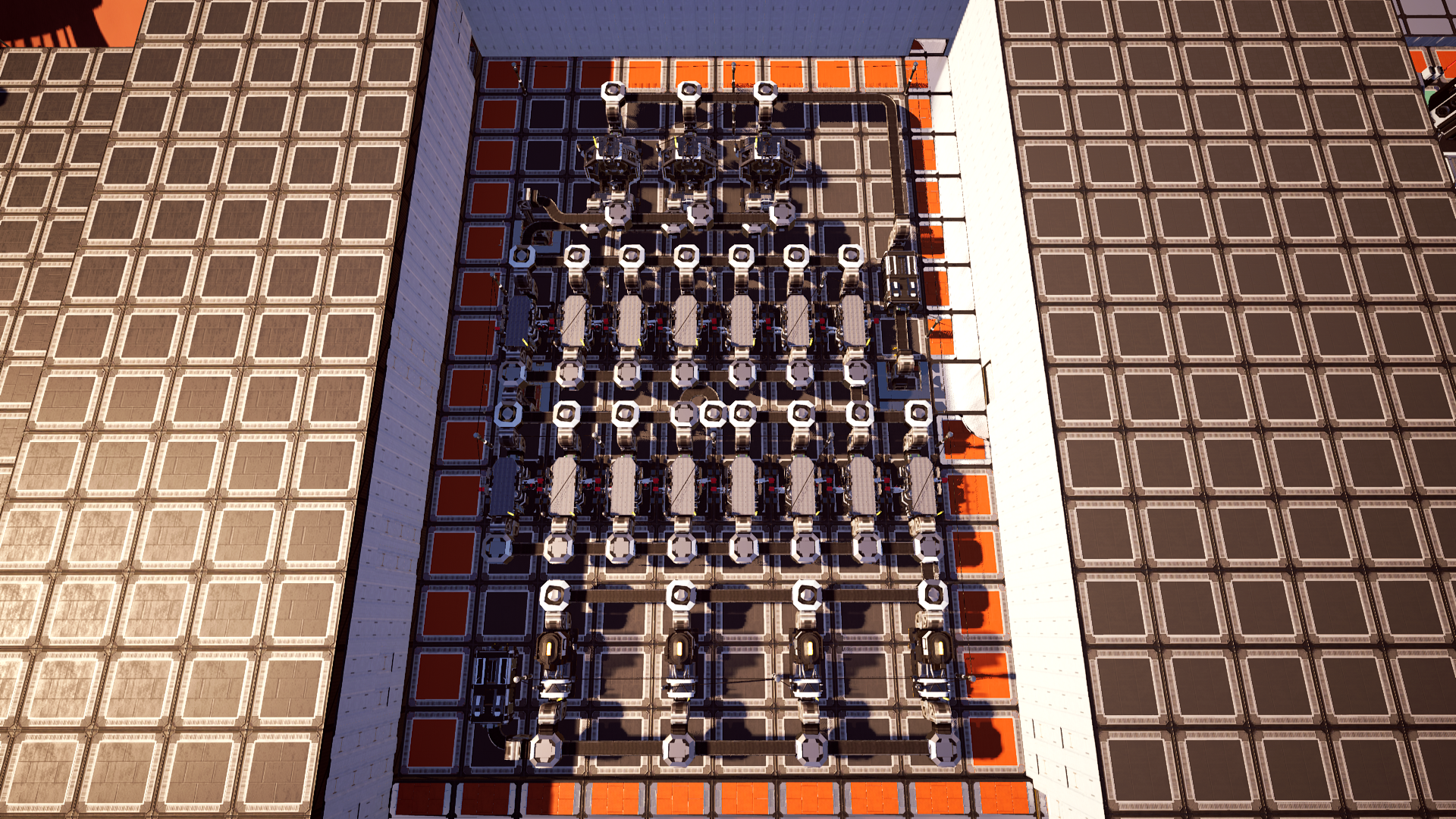

Setup Size: 8x13

Smelter - x4

Constructor - x15

Assembler - x3

Iron Ingot - 112.5/min.

Rotor - 10/min.

Foundations:

Set up a 8x13 grid. For the remainder of this build, the 8 foundation long width will be

the X axis- or Rows, and the 13 foundation long length will be the Y axis- or Columns.

Smelters:

Ensure the 1st row on the X axis remains clear for a Mk.2 manifold bus. Proceed by

placing smelters in the 2nd, 4th, 6th, and 8th columns, positioned centrally on their

respective foundations. Next, construct a merging line by stacking mergers three-high,

directing the first three mergers to the right, while the 4th merger faces forward.

Connect each smelter to the mergers using elevators, and link them together with Mk.2

conveyors. To optimize production, set the 4th smelter to 75% clock speed, while the

remaining three smelters operate at 100%.

Iron Rod Constructors:

Place eight constructors along the 5th row, ensuring they are centered on their

foundations. Position splitters two steps behind each constructor, directing the outputs

to the left. The exception is the splitter behind the 8th constructor, which should be

oriented to face forward. This arrangement will ensure a smooth distribution of

resources to the next phase of production.

Merging Lines:

For Line 1, place mergers in front of the first three constructors, directing the iron

rods beneath the next row. Add a splitter in front of the 4th constructor to manage the

flow.

For Line 2, position a merger beside the splitter, guiding the remaining rods toward

screw production. Merge the outputs from the last three constructors, directing them to

the right.

Screw Constructors:

Place seven constructors along the 8th row, spanning columns 1 to 7. Adjust the first

six constructors to run at 100% clock speed, while setting the 7th constructor to 25%

for optimal production efficiency.

Assemblers:

Place three assemblers along the 11th row and set up dual manifolds to supply both

screws and rods. Merge the outputs into a single line, directing the rotors to a storage

container. To optimize production, set one assembler to 50% clock speed, while the other

two run at 100%.